About

A-Resins | Rotomoulding Polymers is a new brand in the rotomoulding industry, supplying polymers for engineering applications. The first product, ROTARES 1220, is a newly developed, high performance thermoplastic polyester for demanding applications.

For its development, A-Resins | Rotomoulding Polymers has collaborated with the Polymer Processing Research Centre of Queen’s University in Belfast.

ROTARES 1220 in Fuel Tank applications

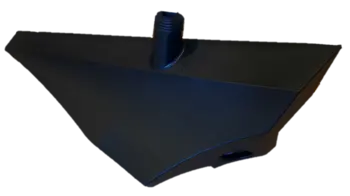

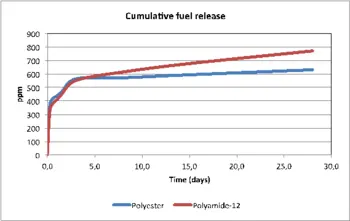

Due to its high chemical resistance for oils, diesel and (bio)fuels combined with a very low evaporative emission similar to polyamide, ROTARESINS 1220 polyester is very suitable for the production of fuel tanks

Fuel tank for heavy-duty machine

Inserts rotomoulded in the fuel tank

Cumulative fuel release out of a rotomoulded polyester and polamide-12 fuel tank (at 40°C)

ROTARES 1220 in decorative applications

ROTARES 1220 is paintable, delivering a smooth surface without pinholes. Due to its high stiffness and good impact, durable decorative applications can be made with this polyester.

ROTARES 1220 : main characteristics

ROTARES 1220 is a high performance thermoplastic polyester for rotational moulding.

It is a newly developed material and Patent Pending.

ROTARES 1220 is designed for specialty and engineering applications with

For some rotomoulding applications, this thermoplastic polyester can replace current polyamide resins.

Other uses are applications where the commodity materials (PE, PP) are technical unsuitable, and when polyamide (-11 and -12) resins are too expensive.

- high temperature resistance

- high stiffness with good impact properties

- excellent chemical resistance for fuels, greases, oils, biofuels

- very low evaporative emission for hydrocarbons

- very low dielectric constant (electrical insulator)

- nice surface characteristics with good scratch resistance and absence of pinholes

- paintable

- not suitable for acids and bases

Applications

Structural parts

containers for hydrocarbons

design applications

furniture

electric appliances

battery hoses

etc.

Processing conditions

ROTARES 1220 polyester can be processed on any convential rotational moulding machine, nitrogen blanketing is not required.

ROTARES 1220 can also be processed in electrical heated moulds.

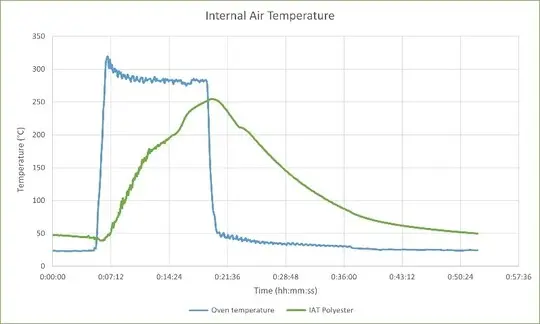

A PIAT between minimum 245°C and maximum 255°C must be respected (Peak Internal Air Temp.).

It is recommended to keep the product dry prior use for production.

Internal Air Temperature on gas oven rotomoulded machine (data PPRC – Queen’s University Belfast)

Table of Properties

|

Property |

Typical value (*) |

Unit |

Method |

|

Melt Volume Index (230°C-2,16kg) |

17 |

g/10min |

ISO 1133 |

|

Density |

1,25 |

g/cm3 |

ISO 1183 |

|

Melting point |

223 |

°C |

ISO 3146 |

|

Tensile modulus |

1165 |

MPa |

ISO 527 |

|

Yield stress |

38 |

MPa |

ISO 527 |

|

Stress at break |

24 |

MPa |

ISO 527 |

|

Strain at break |

375 |

% |

ISO 527 |

|

Flexural modulus |

1250 |

MPa |

ISO 178 |

|

Flexural strength |

43 |

MPa |

ISO 178 |

|

Impact – Charpy notched (23°C) |

15 |

kJ/m2 |

ISO 179 |

|

Packaging |

20 kg bags |

||

(*) Data not intended for specification purposes

Contact

A-Resins | Rotomoulding Polymers is a brand of Polymer Invent BV

Address: Vandendriesschestraat 25, box 4, 9620 Zottegem, Belgium

Registration number 0847.834.735

Contact: geert.jackers@polymerinvent.com | info@a-resins.eu